Home » Swint Friday's Articles » HOT TOPICS

Category Archives: HOT TOPICS

Americans Now Need at Least $500,000 a Year to Enter Top 1%

One definition of rich is getting into the top 1%. If that’s your goal, it’s becoming harder to reach.

The income needed to exit the bottom 99% of U.S. taxpayers hit $515,371 in 2017, according to Internal Revenue Service data released this week. That’s up 7.2% from a year earlier, even after adjusting for inflation.

Since 2011, when Occupy Wall Street protesters rallied under the slogan “We are the 99%,” the income threshold for the top 1% is up an inflation-adjusted 33%. That outpaces all other groups except for those that are even wealthier.

To join the top 0.1%, you would have needed to earn $2.4 million in 2017, an increase of 38% since 2011. The top 0.01% threshold has jumped 46%.

Meanwhile, the top 0.001% — an elite group of 1,433 taxpayers — earned at least $63.4 million each in 2017, up 51% since the Occupy protests.

(more…)Married Men Are Earning Much More Than Others in America

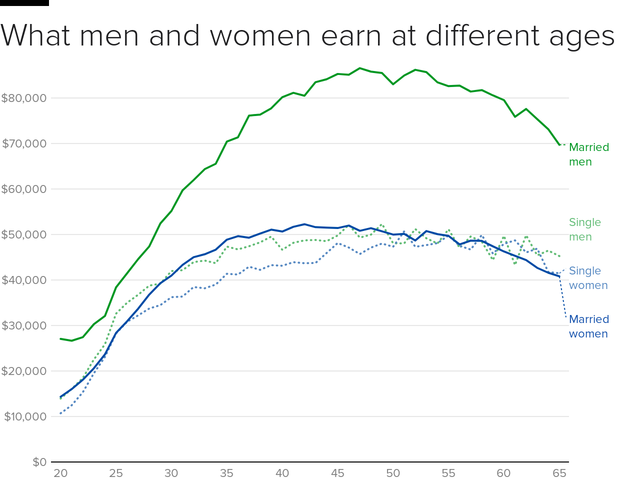

For men, the message is simple. If you want to get paid, get married. For women, unfortunately, working life still presents an seemingly inevitable loss of parity — at least according to new data from the St. Louis Fed.

Married men far outpaced single men and single and married women in their wages and salary through their careers, according to the report. Unmarried men and women have very little difference in income, according to the analysis of all people employed in 2016 with at least a high school diploma. But for women, getting married does little to improve wages, the St. Louis Fed study found.

Married Men Sit Atop Earnings Ladder

Source: Guillaume Vandenbroucke, St. Louis Federal Reserve

Note: Wage and salary income of workers with at least a high school diploma by age, gender, and marital status

The data doesn’t necessarily mean that being married increases a man’s wages, according to the analysis by Guillaume Vandenbroucke, a research officer at the Fed. It may mean men earning higher wages are more likely to marry and lower-income men remain single, the Fed found. Also, married and single women make similar wages, which is “not consistent with the view that the gender wage gap results from women having children earlier in life and losing ground in human capital accumulation relative to men.”

“The gender wage gap remains a complicated topic,” Vandenbroucke wrote in the summary. “But progress may come from asking different questions: not just why women earn less than men (although not compared with single men), but also why married men earn so much more than everyone else.”

By Jeff GreenWatch U.S. Oil Drilling Collapse—and Rise Again

By Tom Randall and Blacki Migliozzi

While two dozen nations are coordinating to cut oil production and rein in the global supply glut, U.S. producers are moving in the opposite direction. Over the last four months, output increased by half a million barrels a day. If that rate of expansion continues, the shale boom will break new production records by summer.

https://www.bloomberg.com/graphics/2017-oil-rigs/

After the global plunge in oil prices began in late 2014, producers began shutting drilling operations at an unprecedented rate. The number of active oil and gas rigs plummeted 80 percent to the fewest since Baker Hughes started tracking them in 1940.

The industry that’s returned has been transformed. It employs fewer workers per rig and is even more tightly focused on the rich shale formations that drove America’s oil and gas boom before the crash. Almost 90 percent of the rigs added during the rebound have been of the horizontal variety.

Wall Street’s Trick or Treat

Wall Street wants you back!

If you were one of those investors who this past spring “sold in May and went away,” you should know that the seasonal winds will soon shift and begin blowing in a bullish direction.

I’m referring, of course, to the well-known six-month-on, six-month-off seasonal pattern that goes by the name of the “Halloween Indicator.” Followers also refer to it as “Sell in May and Go Away.” In contrast to most of the alleged patterns that Wall Street claims to have discovered, this one turns out to be based on solid statistics. The stock market historically has produced the bulk of its gains in the “winter” months between Halloween and May Day.

STORY FROM HYATT

When his football career ended, he became an Opera sensation

Since the Dow Jones industrial average was created in 1896, for example, it has produced an average winter gain of 5.2%, versus just 1.7% during the summer. Not only is this difference significant at the 95% confidence level that statisticians often use to determine if a pattern is more than just a random fluke, it is not unique just to the U.S. Ben Jacobsen, a finance professor at the TIAS Business School in the Netherlands, has detected the Halloween Indicator in almost all foreign countries’ stock markets as well, and as far back as 1694 in the United Kingdom’s market.

(more…)

San Francisco is getting tiny self-driving robots that could put delivery people out of a job

A robot that looks like the love child of an icebox and R2-D2 pulls up outside a house in San Francisco. The lid pops open, uncovering a box of pastries inside.

“I got a delivery from a little roaming cooler, it looks like,” Julie O’Keefe, 67, tells the San Francisco Chronicle.

A recent test run of startup Starship Technologies’ autonomous robot shows what may be the future of on-demand delivery. The London- and Estonia-based company developed a fleet of delivery bots that aim to crack the last-mile challenge, or make the last leg of a delivery.

The startup has already begun testing in Europe, encountering more than a millionpedestrians, and plans to start tests in the Bay Area in the next couple of months.

(more…)

Using 3-D printing to make jet engines

- Source: FORTUNE

A worker ensures the dimensional conformity of a prototype pattern. Today Alcoa can 3-D print the dies used to manufacture turbine parts.Courtesy: AlcoaAlcoa’s embrace of additive manufacturing allows it to turn ideas into reality faster.

Company Snapshot

Name: Alcoa

Ranking: 130

Headquarters: New York City

Employees: 60,000

Revenue: $23 billion (2013)

If you’ve spent any amount of time in an aircraft about to take off—gazing out the window at the tarmac, thinking about the cold beverage you’ll have at altitude—you’ve probably spent at least a passing moment wondering how exactly manufacturers make sure the iron birds don’t break. The answer is materials science, of course. But that’s not the whole story.

There’s a great deal of testing that goes into airplane parts to be sure they can handle the temperatures and stresses of aviation. Alcoa would know. The metals producer, more than 125 years old, makes parts for gas turbines, the engines that plane manufacturers such as Boeing and Airbus install to give planes the power to get you to your next meeting. The problem? All that testing takes time. Between tooling, development, and casting, it used to take Alcoa upwards of a year to manufacture one of the nickel-alloy parts that go into an engine, where it must withstand temperatures of up to 2,000˚F. Then the company caught wind of something called additive manufacturing—better known as 3-D printing.

World’s first 3-D printed cars go on sale next year

Chris Woodyard, USA TODAY8:05 p.m. EST November 7, 2014

LAS VEGAS — For those frustrated at having to search dealers’ showrooms for just the right set of wheels, along comes an innovation that could make creating a custom-made car as easy as a few keystrokes.

A Phoenix company said this week that it plans to produce what it’s calling the world’s first 3-D printed car. Local Motors says it plans to make them available for sale in about a year at prices ranging from $18,000 to $30,000.

The basic idea is simple: Buyers would be able to select their ideal car on a computer screen, then hit the print button. A giant machine would then start making the car out of carbon fiber-reinforced plastic, weaving it out of thin lines of paste that harden to form the chassis, body and even the dashboard. The process takes about 40 hours.

Some of the car’s major components are then attached to complete the car, such as the wheels, controls and powertrain.

Instead of about 25,000 parts in some modern cars, Local Motors says the prototype that it’s showing off last week in Las Vegas at the Specialty Equipment Market Association (SEMA) trade show has about 50.

Because the car is easily changed on a computer screen, it can be shaped to however the buyer would like it, says CEO John “Jay” Rogers.

“If I want this car to be 10% bigger, I just click a button,” he says.

Don’t like the model called the Strati after all? Hang on to it for a few months, then go and choose another model. The 3-D-printed car will be recyclable as long as it has not been painted, Rogers says. Buyers quick to change fashions can grind up their existing car into fine particles again and use the materials to make a new model.

Rogers says the car will pass safety tests. And unlike other cars that can take months for improvements, Local Motors can change any part of its cars with a few keystrokes, allowing changes within hours of a crash test.

The notion of a 3-D-printed car “sounds feasible at some point,” says John O’Dell, an editor for Edmunds.com who specializes in eco-friendly cars.

He noted that handcrafters have made one-of-a-kind cars for generations, so the notion of a car made just for a particular person isn’t entirely new. Those cars, however, were generally not the for the masses. Rather, they appealed to the whims of the super-rich in the past century.

So O’Dell says he’ll watch with interest to see if Local Motors can pull off the idea of 3-D printed cars for the masses.